In general, it may be said that the quality of aircraft produced

was greatly reduced dining the last 6 months of the war. The

reasons for this reduction was the lack of equipment and supplies

caused by bombing of factories and the blockading of the shipping

lanes.

The documentary evidence of quality tests on airframes, engines,

and raw materials was burned. All of the information was obtained

through interrogation of Army and Navy officials.

The quality of the airframes is a rather difficult thing to

evaluate in terms of requirements. It was stated by officials that

because of the thin distribution of skilled labor the quality of

airframes dropped off considerably. A large factor affecting

airframe quality was the poor construction of jigs and fixtures.

Poor jigs made interchangeability practically impossible. This, of

course, resulted in a falling off of quality.

The test flight for aircraft at the beginning of the war and up

until the last few months was 2 to 3 hours with five landings. At

the end of the war an aircraft often received its test flight while

enroute to the air depot where it was to be delivered. Again the

reason for lowering standards was the shortage of fuel. Many of the

training planes received no test flight at all.

One engine out of every 10 was withheld and broken down for a

friction inspection and then given a test run. At the outbreak of

the war, all engines received this type of inspection, but, as the

time factor entered hi this, short cuts were made.

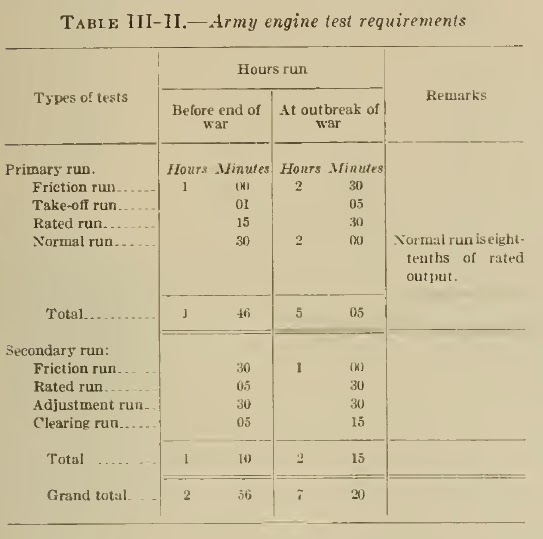

At the outbreak of the war the Army required approximately 7

hours running-in-time on engines, while the Navy required about 9

hours. These figures represent an average because some engines

required more time and trainer engines and such required far

less.

Table III-II shows the Army standards at the outbreak of the war

compared with those just prior to the close of the war. Friction

runs were a more drastically curtailed phase of the inspection.

No comments:

Post a Comment